Call Us :

info@saspowder.com

Call Us :

We are proud of the Arabian Peninsula in western Asia, manufacturer of custom powder coatings located in the Industrial Area, Riyadh.

Our powder coating adds value to your products so they stand out from the crowd. We offer a complete range of powder coatings and specialty finishes in a number of systems including Super durable, Fast Cure & Low Bake.

Our R&D and QC Department. are skilled to match any color and pattern for product lines in less than one week. We continuously develop and produce high quality environment friendly products using current technological standards and raw materials. Our core strength is our CONSISTENCY in all aspects of this business, be it powder chemistry, availability, appearance, flow or service

Contact one of our sales reps and we will be happy to be of service.

Powder Coatings are Durable, Attractive, and Long-Lasting

Powder coatings are durable, attractive, scratch-resistant, long-lasting and environmentally responsible when compared to other finishes. Used for protective and decorative purposes, powder coatings are available in an almost limitless range of colors and textures, and technological advancements have resulted in excellent performance properties. While powder coatings are 100% solid with virtually zero VOCs, they are easy to apply and give you not only an attractive finish but a protection for assets for many years.

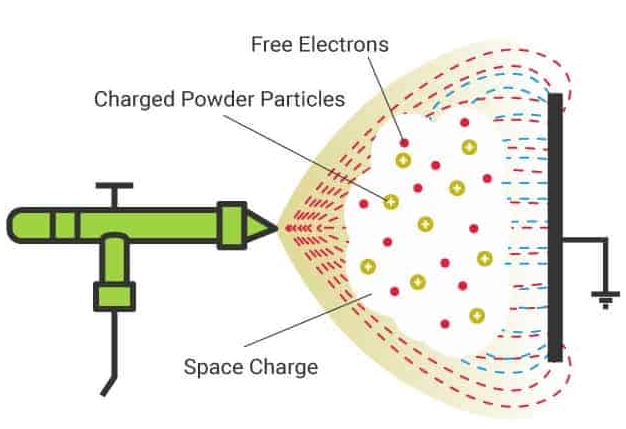

Powder coatings are based on polymer resin systems, combined with crosslinkers, pigments, leveling agents, flow modifiers, and other additives. These ingredients are melted, mixed, cooled, and ground into a uniform powder. A process called electrostatic spray deposition (ESD) is typically used to achieve the application of the powder coating to a metal substrate.

This application method uses a spray gun, which applies an electrostatic charge to the powder particles, which are then attracted to the grounded part. After application of the powder coating, the parts enter a curing oven where the coating chemically reacts to produce long molecular chains, resulting in high cross-link density. These molecular chains are very resistant to breakdown. This type of application is the most common method of applying powders.

Sometimes a powder coating is applied during a fluidized bed application. Preheated parts are dipped in a hopper of fluidizing powder, the coating melts and flows out on the part. Post cure may be required depending on the mass, temperature of the part and the type of powder used. No matter which application process is utilized, powder coatings are easy to use, environmentally friendly, cost effective, and tough! Durability.

Powder coating is a high-quality finish that is found on thousands of products you come across every day. It protects and beautifies anything from machinery, buildings, playgrounds, furniture to household items you use daily. Powder coatings are preferred because of their durable and attractive finish and are more resistant to impact, moisture, chemicals, UV light and extreme weather conditions. Plus, they are a great choice because of their environmental advantages